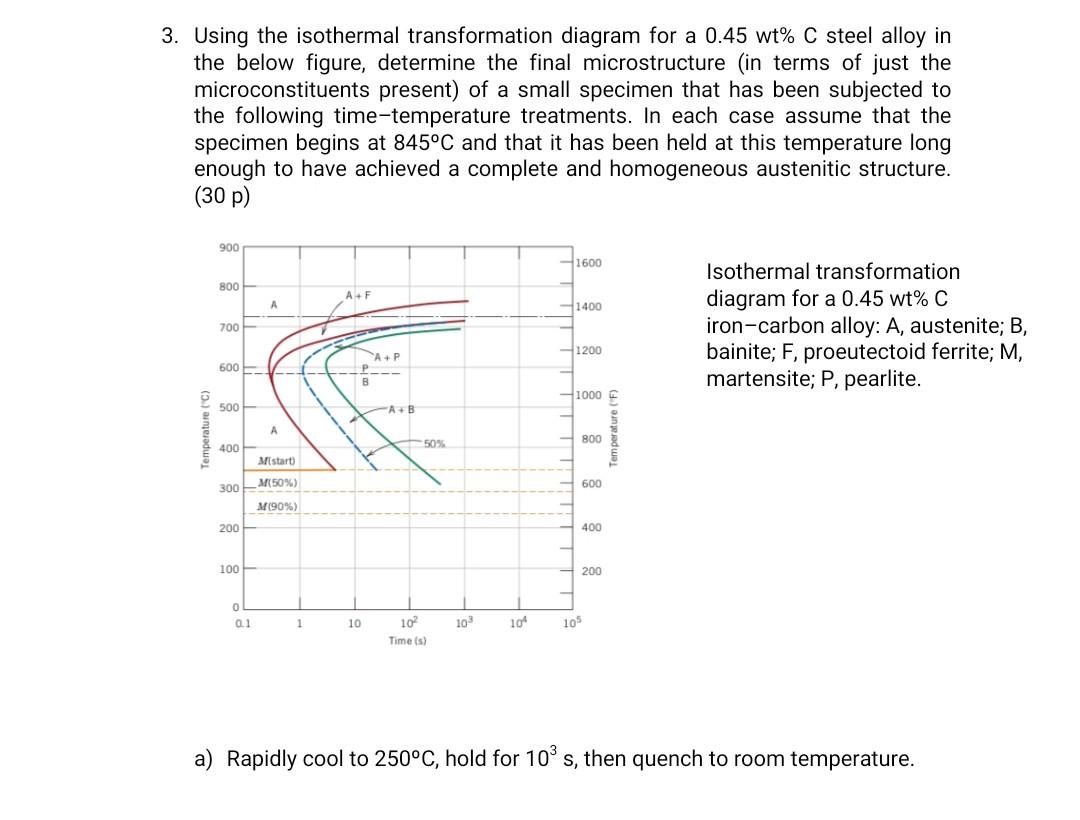

Solved b) Rapidly cool to 625°C, hold for 1 s, then quench

4.6 (626) · € 28.00 · Auf Lager

Mate210final Flashcards

Solved Using the isothermal transformation diagram for an

Solved] 1) Using the isothermal time transformation (TTT) diagram (below)

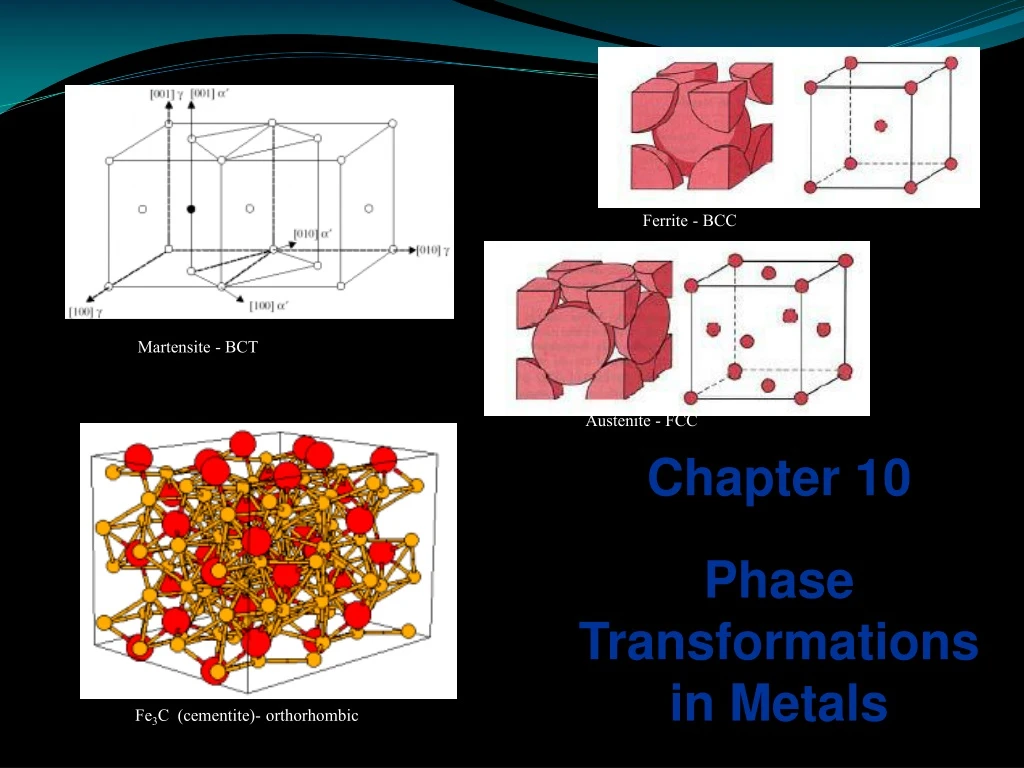

PPT - Chapter 10 Phase Transformations in Metals PowerPoint Presentation - ID:8584967

6 Process variants for producing hot-rolled and cold-rolled austenitic

US11701373B2 - Substituted bicyclic compounds - Google Patents

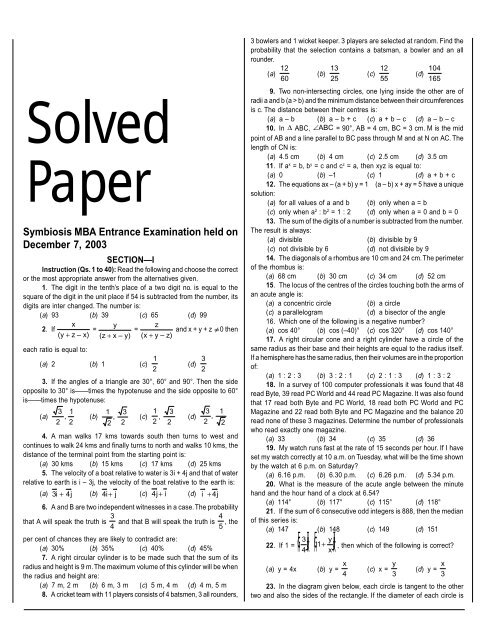

Solved Paper

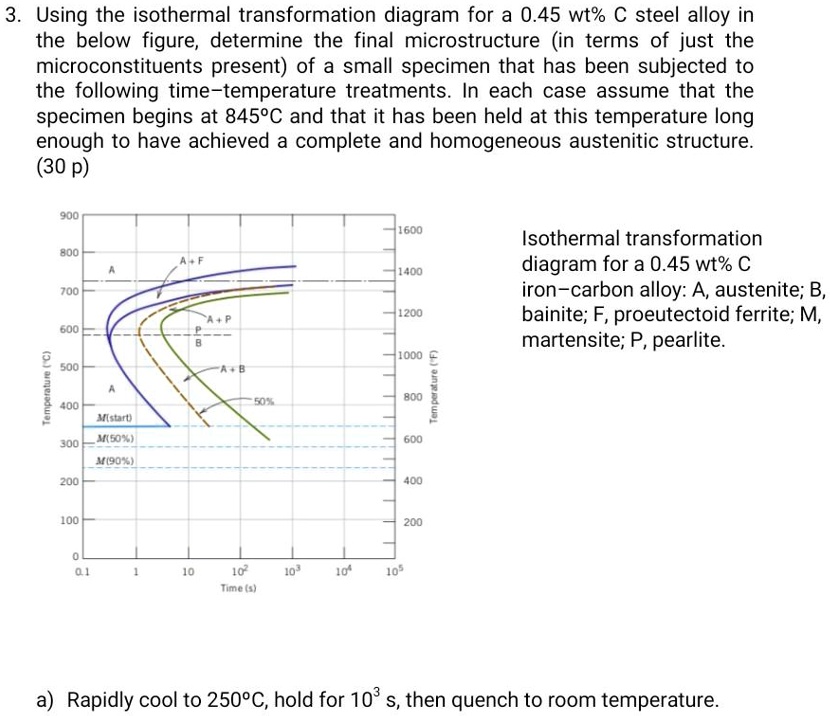

a) Cool rapidly to 350°C (660°F), hold for 103 s, then quench to room temperature. (b) Rapidly cool to

926-39-6, 2-Aminoethyl hydrogen sulfate

SOLVED: Using the Animated Figure 10.40, the isothermal transformation diagram for a 0.45 wt% C steel alloy, specify the nature of the final microstructure (in terms of the microconstituents present) of a

Quench Sensitivity of 7475 Aluminum Alloy Using End-Quenching Technique and TTP Diagrams

SOLVED: b) Rapidly cool to 625°C, hold for 1 s, then quench to room temperature. 3. Using the isothermal transformation diagram for a 0.45 wt% C steel alloy in the figure below

:strip_icc():strip_exif()/images/item-images/dabag-ftp/17643_490882_2003_01.jpg)